Centro de noticias

Publicado el 5 de April de 2017 Soluciones

• Que tenga la suficiente fuerza de retención, igual al menos a la cantidad declarada, + o – 10%

• Que haya recibido un tratamiento efectivo contra la corrosión

• Que no tenga magnetismo residual incluso después de 30 años de uso continuo

En los primeros años que siguieron a la introducción de los electroimanes en Europa, emergieron varios competidores, principalmente fabricantes industriales, que iniciaron en Alemania y el norte de Europa su propia producción en fábricas europeas. Estos productos eran en general comparables a los nuestros, tanto en calidad como en precio.

Años después, otros actores invadieron el mercado, no ya motivados por un espíritu industrial, sino por un interés puramente comercial. Su único leitmotiv era el de vender más barato un producto que se pareciera al original.

La respuesta viene de un laboratorio oficial que ha testado los conocidos como cierres «300 kgf» en el mercado europeo.

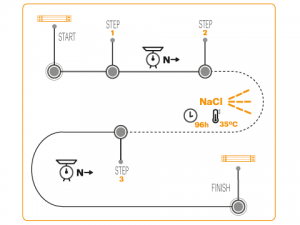

Pruebas realizadas con nuestras ventosas al mismo tiempo que se analizaban los electroimanes de nuestros competidores.

Más detalles en el estudio completo que se incluye a continuación.

Estudio completo ………………….DESCARGA

Últimas noticias